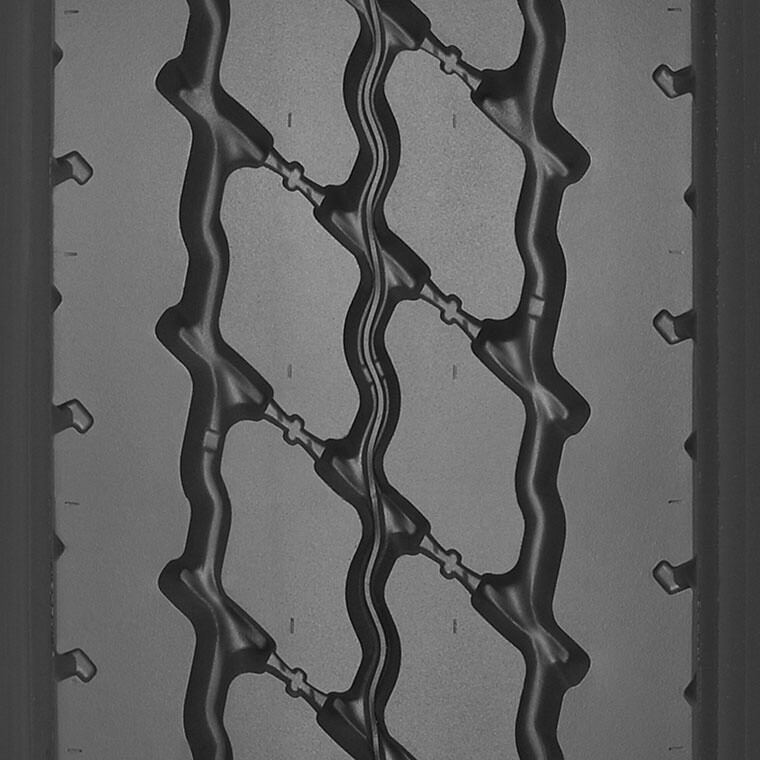

MICHELIN XZY®3 Pre-Mold Retread

All-wheel position tread designed for exceptional wear and all-position traction in mixed on/off road service. Abrasion resistant compound promotes long casing and tread life.

Wait until we verify sizes...

4 sizes for this tire

Technical specification

| Casing size | 385/55R22.5 |

|---|---|

| Tread Width | 290 mm |

| Tread Depth | 22 /32nds |

| MSPN | 60179 |

Technical specification

Technical specification

| Casing size | 385/55R22.5 |

|---|---|

| Tread Width | 290 mm |

| Tread Depth | 22 /32nds |

| MSPN | 60179 |