michelin background mrt mast desktop tire

MICHELIN® RETREAD TECHNOLOGIES

AN ENVIRONMENTALLY FRIENDLY WAY

TO PROTECT YOUR BOTTOM LINE

WHY RETREAD?

Retreading your tires is good for the environment and for your business.

Discover a way to get the most out of your tires when you choose to embrace the retread process.

REDUCE TIRE TOTAL COST OF OWNERSHIP (TCO)

- A casing is 70% of the value in a new tire purchase

- A retread is 35% of the cost of a new tire

- A retread delivers 80% of the mileage of a new tire

REDUCE ENVIRONMENTAL IMPACT

- Saves 380 million+ litres of oil annually1

- Millions of tires that would end up in landfills yield thousands more kilometers1

¹retread.org/learn-more

WHY MICHELIN® RETREAD TECHNOLOGIES?

Our innovative retread process creates retreads you can trust to save money and keep your trucks on the road. Utilizing Michelin's new-tire design technology, proven tread designs and new-tire manufacturing standards, the MICHELIN® Retread Technologies (MRT) retread process delivers reliable retreads, designed for your application to help you maximize your tire assets.

- Low rolling resistance, SmartWay® verified retreads for maximum fuel efficiency

- Michelin proprietary technology that yields multiple retreads

- Monitored and audited, 9-step manufacturing process delivers uniform results

- Increased accountability of your assets with Bib Tread mobile on-site digital app

- Consistent, nationwide retread warranty backed by Michelin

MRT 9-STEP MANUFACTURING PROCESS

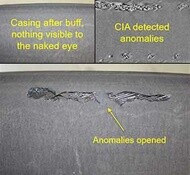

Every casing, every detail, inspected every time - Enables trained operators to detect subtle irregularities that may indicate internal damage such as zippers

michelin edito mrt accordion 1 initial inspection tire

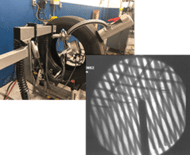

Computer automated, guided by casing-specific database and sensors - Provides under tread of optimal profile, depth and texture

michelin edito mrt accordion 2 buffing tire

Two-step laser photography performed on every tire - Reveals separations or blisters within the belts or other areas of the casing not visible to the operator

michelin edito mrt accordion 3 cia tire

Available and used when needed - Allows visual inspection of the steel belts within the casing

michelin edito mrt accordion 4 x ray tire

Best practice repairs - Thermal curing along with mechanical pressure exceeds industry standards

michelin edito mrt accordion 5 repair tire

Uses MICHELIN® patented new tire tread patterns, rubber compounds and technology - Combines two operations into one by applying hot cushion gum and pre-molded tread on the same machine

michelin edito mrt accordion 6 tread building tire

Unique use of inner envelope applies pressure to both sides of the repair - Ensures that every surface of the retread undergoes uniform pressure and temperature

michelin edito mrt accordion 7 double enveloping tire

Computer controlled for minimum temperature variations - Achieves optimal uniformity and enhances full integration of all repairs

michelin edito mrt accordion 8 curing tire

Assurance of the best retread every time - Thorough inspection of crown, sidewall, bead and interior

michelin edito mrt accordion 9 final inspection tire