Background axiobib2 at work Help and Advice

TRacteur équipé de pneus MICHELIN AXIOBIB2 dans un champ

Mounting and dismounting your tires

Mounting and dismounting agricultural tires must be performed by an expert using proper equipment. If more than one person is helping with this process, ensure that at least one person is monitoring the process at all times. Use a compressed air system equipped with a correctly adjusted pressure relief valve. Failure to follow these instructions may result in an incorrectly mounted tire, or rapid air loss-resulting in serious injury or death.

Removing the tire from the rim

Edito photo demonterttalon ag Help and Advice

disassemble a wheel

1. Do not attempt to remove the beads of an inflated agricultural tire from a rim.

2. It is IMPERATIVE to remove the inner mechanism of the valve:

- Make sure that the tire is completely deflated before disassembling

- Do not use tools that could damage the sides or beads of the casing

- Remove the beads from the removal notches, if equipped

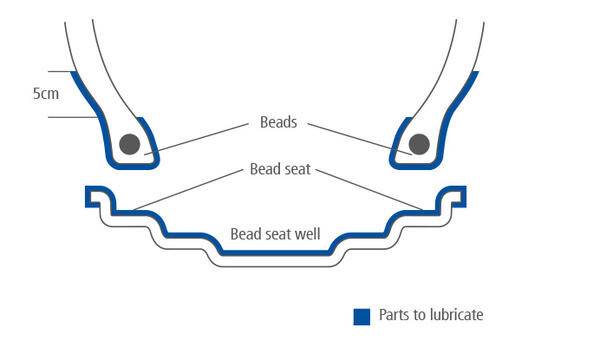

- Lubricate the rim seat and tire beads to facilitate removal and to avoid bead damage, especially during a puncture repairs

- If the rim is visibly damaged, deflate the tire before trying to dismount.

Preparing for Installation

Edito photo demonter pneu large reference Help and Advice

triptich picture of a man removing a tyre

1. Before mounting, make sure that the rim, tire and inner tube are compatible, check if:

- The rim is compatible with load and pressure requirements

- The tire is suitable for the vehicle or machine

- The seat diameter of the rim corresponds to the seat diameter of the tire to be mounted (Example: Casing 18.4 R 30 Rim: DW16L x 30),

- Tire mounting is permitted on this rim

Warning: there are rims with 15.3” seat diameters, never install 15” tires on these rims. Similarly, for 16.1” and 16.5” diameter rims, never mount 16” tires.

2. On a rim that has already been used, before mounting: The rim must be clean and undamaged. Once inspected, clean the rim with a wire brush. Warning: Never mount a tire on a cracked or bent rim, or that shows signs of breakage, weld repair marks, etc.

3. If the tire is worn, carefully examine the outside and inside for any damage that needs to be repaired before installation. If the tire shows any damage or signs of wear that a specialist deems unrepairable, remove the tire.

4. When mounting with an inner tube, always use a new inner tube suitable for the tire (compatible tire sizes are marked on the inner tube). Do not mount an inner tube in a damaged, repaired or uneven rim. For tubeless mounting of a tubeless tire on a tubeless rim, fit a new tubeless valve each time the tire is mounted.

5. Use tools that are in good condition, that are clean and suitable for tires and rims (bead removers, levers, machines, etc.). For large or high volume tires, it is recommended to use a bead pusher or bead breaker (appropriate mechanical assistance) for mounting the second bead. Before mounting, lubricate the casing rim seals and the bulges (beads). Apply a thin layer of lubricant to the parts marked on the sketch. On the outside of the beads, the lubricant should be up to 3 inches higher than the rim flange. Only use products made for this purpose and not harmful for the tire: avoid hydrocarbon, silicone and antifreeze based products.

Mounting the tire on an upright wheel

Edito photo monter pneu vertical Help and Advice

two men fitting a tire

Picto image schema montage optimise reference Help and Advice

schema or installation diagram

1. Position the valve or valve hole at the bottom.

2. In order to avoid tire bead damage, position the calibration window away from the valve location.

3. Fit the tire on the rim so that the first tire bead comes to rest on the rim flange. If necessary, look for an arrow on the tire that shows direction of rotation.

4. Use a suitable lever and tap every 4-6 inches:

- Slide the first bead over the rim flange and push it into the deepest groove.

- Once the first bead has passed: Fasten the valve by gently tightening the nut. If mounting with an inner tube, position the slightly inflated inner tube inside the tire.

- For the second bead: slide the first bead over the rim flange and push it into the deepest groove

- Finish at the valve.

5. Tire centering, bead placement

- Slightly lower the jack to bring the center of the tire closer to the rim.

- Remove the inner mechanism of the valve.

- Slowly inflate for better bead placement.

- If installing with an inner tube, check that the beads do not pinch the tube. To ensure proper bead seating, inflate to, but do not exceed, 25 psi.

Inflating and Positioning the Beads

Pcito ag help advice schema montage fr Help and Advice

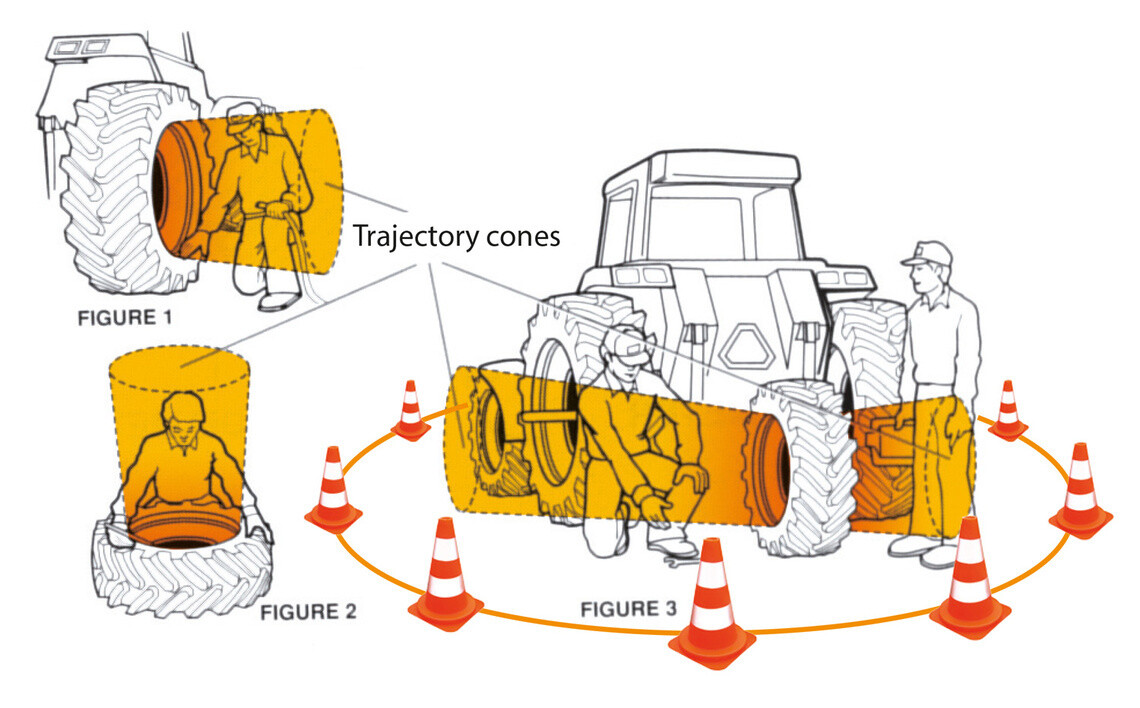

Warning: In the event of an accident and to avoid the risk of personal injury or even death, never stand in possible trajectories. For safety, use an inflation gun with a calibrated pressure gauge, connected to the valve via clip system and an air extension hose of at least 10 feet. Remember to never block the handle.

Safety:

Recommended safety equipment:

• A retention system for agricultural tire units (safety cage)

• Protective goggles

• Safety shoes

• Noise-cancelling helmet. If there is no cage or safety bar, the operator should move as far away from the tire and rim as possible.

Precautions:

First, check:

• That the beads are correctly placed and centered in relation to the rim flanges. Inflate to, but do not exceed, 25 psi.

• If the beads are not correctly in place: deflate, lubricate again and inflate to 35 psi, repeat these steps until the beads are correctly in place.

Next:

• Replace the inner mechanism of the valve.

• Tighten the valve nut by hand.

• Inflate to the air pressure mentioned in the manufacturer's load scales documentation or proper storage pressure.

• Remember to replace the valve cap after any inflation or pressure check--this will ensure valve cleanliness and tightness. Due to the difficulty of seeing the lower bead fitment, if mounting flat on the ground Michelin recommends:

• Not to initially exceed 8 psi (for the sealing connection);

• Lift the tire and rim unit, preferably into safety; however, if one isn't available support the upper part against a wall, never against something that could move;

• Following the inflation instructions for vertical installation (Figures 1, 2 and 3).

Returning to Service

To avoid strap damage when transporting equipment (by road, rail, or ship), we recommend inflating agricultural tires to 26 psi.

Before machinery is returned to service, it is essential air pressure is regulated based on load and conditions of use.

Mounting and dismounting an agricultural tire (EN)

These tips may also interest you:

• Reading and understanding tire markings

• How to reduce soil compaction

• How and why to ballast your tires for optimal use

• Find the right rim, tube, and valve fitments

• Safely store your tires