tires in landfill

Two of the largest companies in the tire industry – Michelin and Bridgestone – have joined forces to create an industry standard that will help create safer, cleaner and more sustainable mobility across the industry.

In a November 2023 report, Michelin and Bridgestone shared their early findings on using more recycled carbon black in tires.

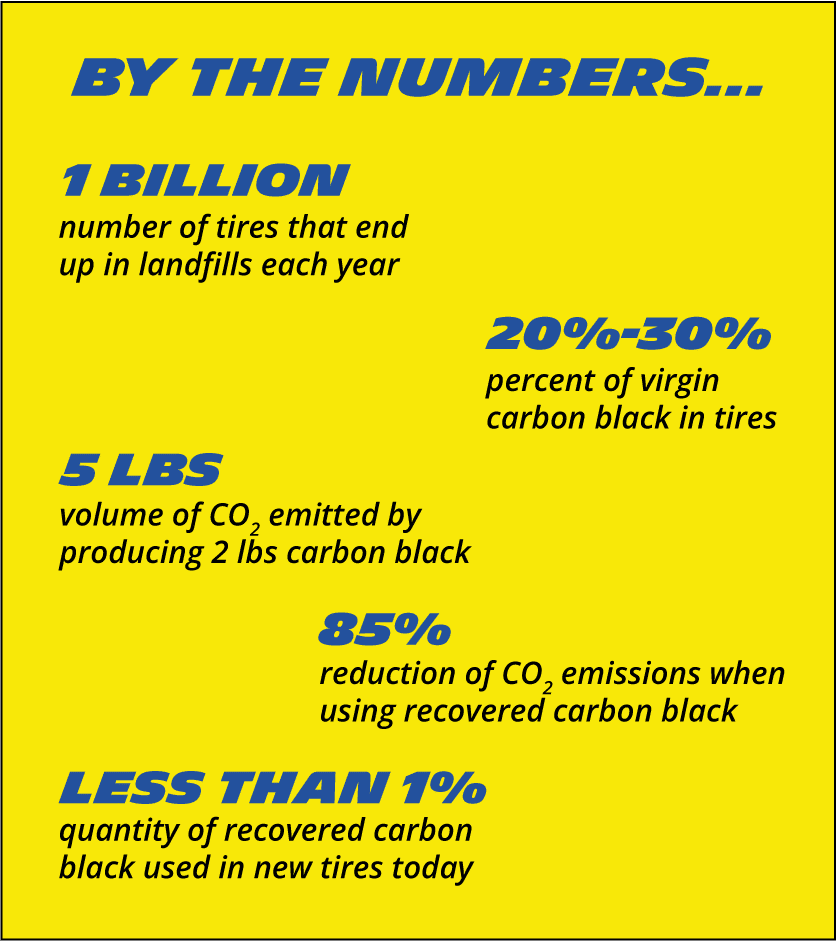

Each year, experts estimate that landfills around the world receive one billion tires that have reached the end of their life. With climate change and environmental issues at the forefront of many conversations, finding a way to recycle or recover the materials from old tires is crucial to creating a cleaner and more sustainable mobility ecosystem.

That is where Michelin and Bridgestone’s collaborative efforts come into play. The companies are working side-by-side to help solve this problem and create less tire waste through the increased use of recovered carbon black (rCB) materials in tires.

“The conversion of End-of-Life Tires into cutting-edge materials that can be reused in our tires marks a significant initial stride towards achieving our goal of 40% recycled and renewable sustainable materials by 2030”, said Fabien Gaboriaud, Senior Vice President of Sustainable Materials & Circularity, Michelin.

What is Carbon Black?

Carbon black is a component found in tires and constitutes about 20%-30% of the tire as it’s used as a filler to help reinforce the rubber so it is more durable on the road. It is also what causes tires to be black in color.

The process of creating carbon black requires the use of fossil resources and produces tons of carbon dioxide – all harmful to the environment. So, the less carbon black that can be created, the less negative impact the production process will have on the environment.

The recovered carbon black market presents an opportunity to reduce the tire industry’s reliance on petrochemicals by replacing a portion of traditional carbon black with a sustainable and circular alternative without introducing performance compromises. Additionally, using recovered carbon black in new tire production can reduce CO2 emissions in new tire production by up to 85% compared to virgin materials.

carbon black powder

pile of coal dust isolated on white background

Carbon black powder

What can be done?

Michelin has a sustainability plan that by 2030, 40% of their tires in circulation are comprised of renewable and recycled material; and by 2050 that rate should be 100%. Bridgestone has a similar plan. In order to meet these plans, both companies have to find a way to make the process of creating tires more sustainable.

One discovery that will help with sustainability efforts is using recovered carbon black in the recycling of tires is much more sustainable than using virgin carbon black – in other words, instead of throwing tires away and the carbon black in them goes to waste and more has to be created, why not recover it and reuse it in new tires?

Many of the technical challenges surrounding the use of recycled and recovered materials from end-of-life tires are understood, but there remain significant market barriers to achieving material circularity at the scale necessary to realize material circularity in tires. Today, fewer than 1% of all carbon black material used globally in new tire production comes from recycled end-of-life tires, due to a sub-optimal supply chain for the recovery and reuse of carbon black.

carbon black infographic

But, as both companies continued to focus on recovered carbon black, they noticed a key trend: the industry has no standards or specifications for supporting the push for rCB or guidelines defining the capacity, demand and technical requirements. Therefore, the use of recovered carbon black is not an established marketplace.

With this discovery, Michelin and Bridgestone decided in 2021 to team up and help define the industry standards to that will boost the usage of recycled and recovered materials in tires going forward.

“No one company can deliver the supply chain advancements necessary to achieve our shared aim of a more sustainable and circular tire economy,” said Marco Musaio, Head of End-of-Life Tire & Circular Economy, Bridgestone Europe. “The use of recovered carbon black in tires is a critical element of our efforts to achieve products that are made from 100% sustainable materials by 2050.”

Where are they in the process today?

In early November 2023, the companies issued a joint white paper, Bridgestone & Michelin: Recovered Carbon Black Guidelines, where they proposed a global standard to increase the use of recovered carbon black in tires.

Bridgestone and Michelin collaborated with rCB suppliers and other stakeholders in the value chain to define initial proposals for standards, including grades, specifications, and awareness of quality and performance requirements for the tire industry.

The two companies have produced a set of definitions, proposed specifications, and guidelines for regulatory requirements, as well as a foundation for supporting the growth of the rCB industry.

“The shift from a linear value chain to a circular one presents a crucial challenge necessitating a shift in mindset and increased adaptability,” said Gaboriaud.

"The partnership between Bridgestone and Michelin serves as a prime illustration of this transition, aimed at fostering the development of a novel value chain for reclaimed carbon black."

Fabien Gaboriaud, Senior Vice President of Sustainable Materials & Circularity, Michelin

What’s next?

While the efforts by Michelin and Bridgestone have laid the foundation for growth in the recovered carbon black industry, there is still work to be done. With an industry standard for rCB, along with continued improvement in quality and performance, the expectation is that the market for rCB will reach up to 1 million tons by 2030 (based on market assumptions and 3rd party expert input).

However, that’s only the start of what needs to be done to create better sustainable mobility. The companies encourage the industry to look into other factors impacting sustainability and help develop a point of view and standard.

An aligned point of view will be a starting point toward standardization in the rCB industry.

Bridgestone and Michelin plan to continue their work to advance and scale sustainable carbon black technologies to meet the future needs of the industry and remove hurdles for their development. This includes further advancement of rCB, but also other pathways such as carbon black produced from renewable oils, or from tire pyrolysis oil. A combination of these technologies are likely to be applied together in order to achieve the common vision of a sustainable supply chain in 2050.

Visit the site to learn more about Michelin and Bridgestone's efforts in the recovered carbon black industry, to read their initial project plan or to get involved.